AMADA strongly believes that innovative software is the core of productive sheet metal processing. With decades of experience in the sheet metal industry and by working together with our customers, we have developed easy to use software solutions designed to meet the industry requirements. AMADA software solutions increase customer productivity through integrated development with AMADA machines and an emphasis on virtual prototyping and simulation systems.

Our VPSS 4ie CAD/CAM software helps you virtually simulate the production process, identify potential issues and make adjustments before manufacturing. With our solutions, you can maximise quality and increase efficiency whilst minimising waste. The fully automated and optimised software can also be used by less experienced operators.

The previous VPSS 3i software concept of Intelligent, Interactive and Integrated has now been broadened. The new VPSS 4ie incorporates the latest innovations in technology (INNOVATIVE), offers an intuitive user experience (EASY TO USE), enhances operational efficiency (EFFICIENCY), meets environmental regulations (ENVIRONMENTAL), and supports continuous evolution (EVOLUTION).

1. PRODUCT FILE IMPORT

Importing, optimising, and designing your parts is key to increasing the productivity of your machine. Thanks to Production Designer, you no longer need to use different CADs or ask your customers for neutral file format conversions.

- ABILITY TO IMPORT A WIDE RANGE OF 2D/3D DRAWINGS – all major CAD formats are supported.

- FROM ASSEMBLY TO SINGLE PART – automatic unfolding drawings creation.

- FROM PAPER TO DIGITAL – unskilled drawing development thanks to AI embedded in our VPSS 4ie.

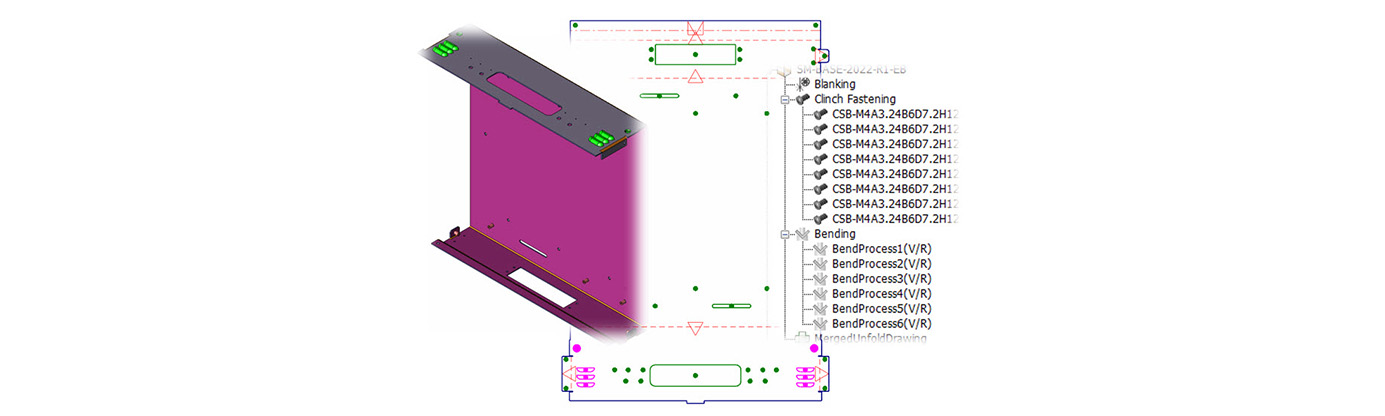

2. SHEET METAL DESIGN

FROM DESIGN TO PRODUCTION-READY IN JUST A FEW CLICKS!

The process of converting a design/concept into a part is straightforward and follows standard and simple steps.

A variety of user-support features (automatic corner relief, hole pattern recognition, bend feasibility check, etc.) will streamline your design-to-manufacturing processes, increasing performance, productivity, and profitability.

3. SHEET METAL MANUFACTURING

You can import your sheet metal model directly into virtual manufacturing and create a production sequence based on the steps your model requires.

Convert the details of your sheet metal model, such as fasteners and forming, into information about manufacturing processes and tools. Check and optimise your unfolding drawing according to the selected machine technology without losing sight of the feasibility.

4. CAM

Within the continuous process chain, the sheet metal model is now passed on to programming. Cross-technology CAM systems maximise productivity and efficiency by automatically generating offline programs and verifying the feasibility of parts.

CAD FOCUSES ON DESIGN; CAM FOCUSES ON OPERATION: reducing waste and energy, increasing productivity, ensuring consistency in raw materials and tooling.

The easy-to-use AMADA CAM systems automatically create the optimal program by unlocking the full potential of the latest AMADA machines (laser welding, bending, robot bending, laser cutting or punching).